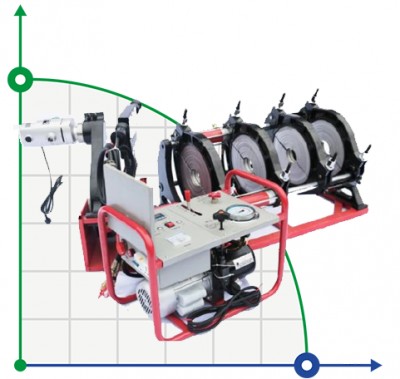

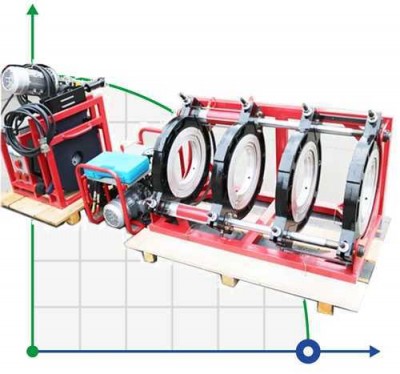

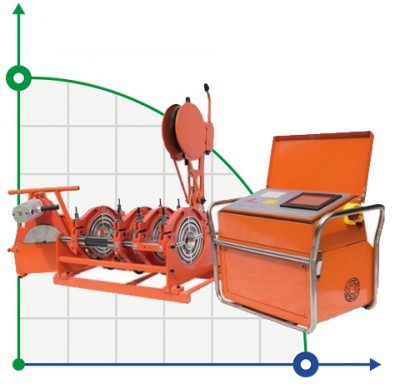

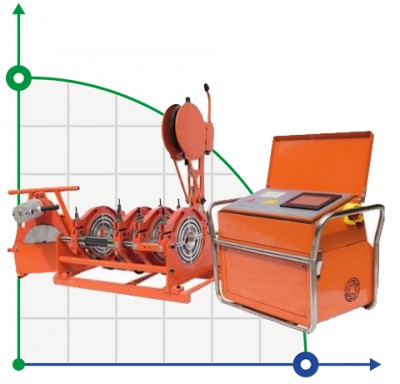

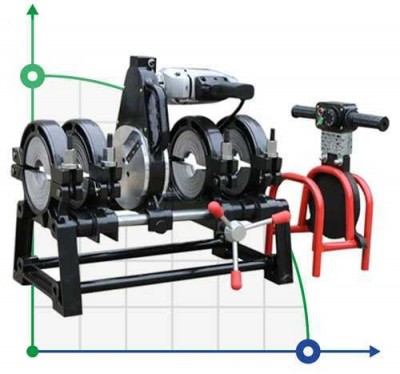

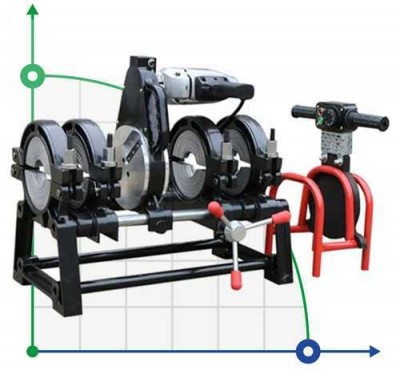

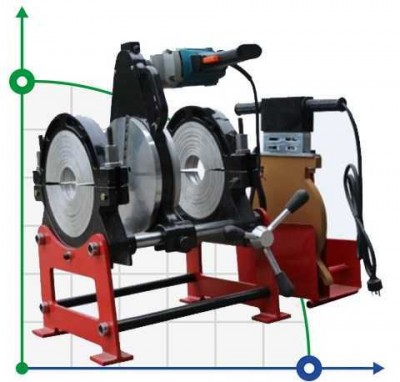

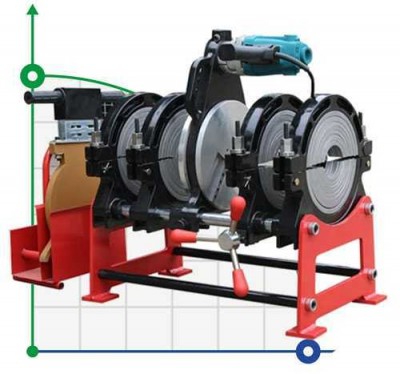

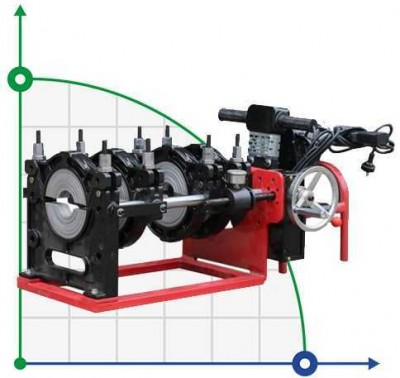

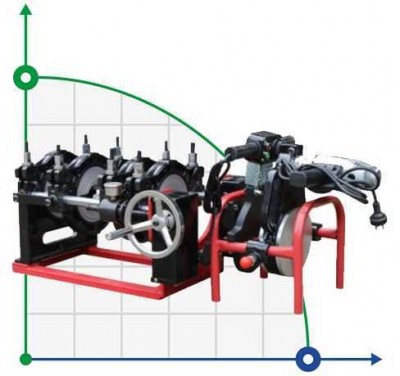

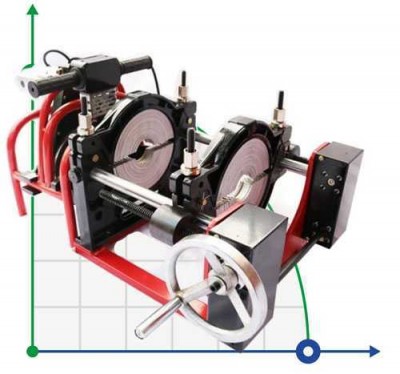

For butt welding, welding machines are used:

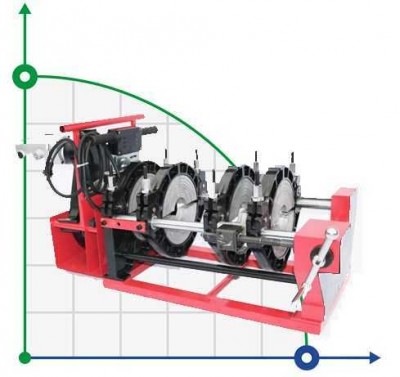

Pipe butt welding, thermistor welding, autogenous welding, thermistor melting, fusion welding, fusion welding, pipe welding machine, pipe welding machine Butt welding machine CNC butt welding machine Hydraulic butt welding machine for pipe Scope of delivery: machine body, milling machine head, hydraulic control heating plate Numerical control mechanism Welding machine support plate, accessories. The butt welding process consists of:

Butt welding provides the connection of pipes with a strength higher than the pipe itself. Heating up to the viscosity of the compound occurs, after cooling there is no change in the physicochemical properties of the material.

The main advantage of butt welding over other methods is that the pipes themselves are welded directly and no additional couplings and joints are needed for welding. Only the polyethylene pipe sections themselves are used. The only drawback of this method is that it is necessary to adhere to all technological welding conditions. In fact, this needs to be done in every process.

Butt welding of polyethylene pipes is used for joining pipes with a diameter of more than 50 mm up to 1600 mm and a wall thickness of more than 5 mm. The principle of this method is based on heating the end parts of the pipes during contact with the heating element, until the required viscosity of the polyethylene pipe is obtained, in order to make the joining of the connecting elements melted at the molecular level.

Insert a heated plate between the ends of the pipes.

Using a vise, squeeze the ends of the pipes to the heater under the required pressure.

Wait for the required amount of time specified in the technical data for melting the pipes or parts to be joined.

Reduce the pressure a little and wait for the ends to warm up.

Remove the heater.

The butt welding process itself after heating consists of:

- connect the abutting polyethylene pipes;

- wait for the structure to cool down.

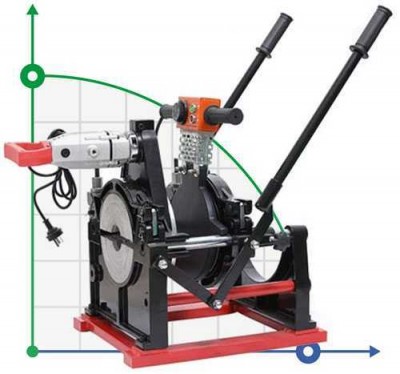

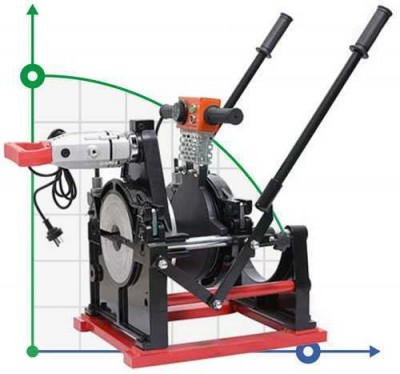

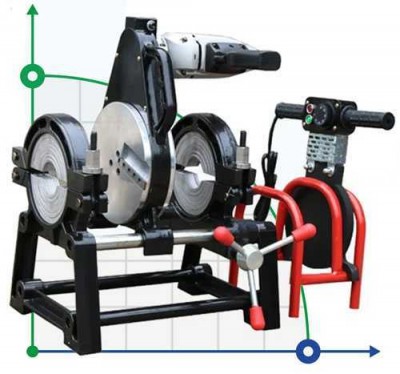

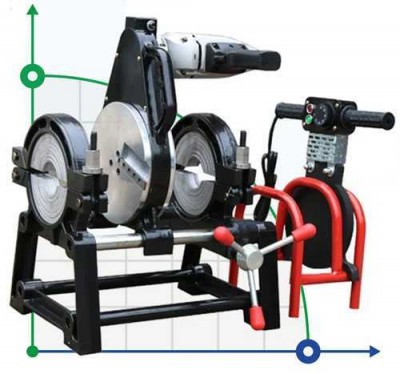

For butt welding, welding machines are used:

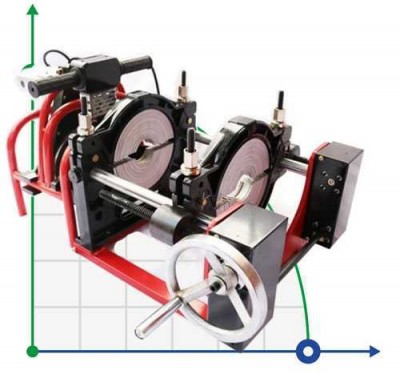

- devices with a manual drive;

- devices with hydraulics;

- devices with an automatic system of work.