The bitumen pump is designed to move amorphous and viscous substances, as a rule, of organic origin: tar, fuel oil, tar, mineral oils, refined products. All these components are used in the production of roofing material, mastic, hydroglass, asphalt and many others.

Bitumen composition: solids, organic oils and resins. At medium temperatures, such a mass, which has a high viscosity, solidifies quickly, so it must be heated for pumping.

Natural bitumens with asphaltene impurities or bituminous oil are difficult to develop. Most often in the industry they use technical bitumen - derivatives and products of oil refining. The composition of both natural and artificial bitumen is similar: solid particles - resins - oils. As a result, bitumen is absolutely non-hygroscopic. The hydrophobic properties of bitumen are extremely high. That, coupled with the plasticity of the properties of this material, depending on the temperature regime, and determines its widespread use.

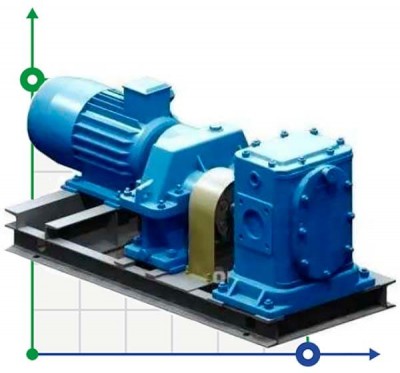

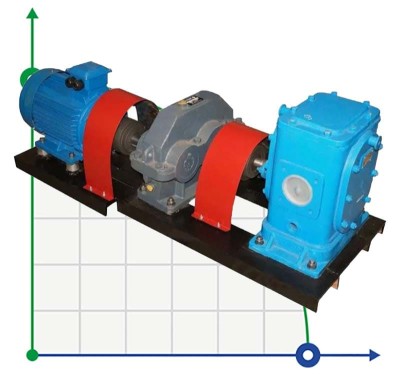

The so-called bitumen pumps, bitumen pumps, gear pumps, screw pumps are widely used for pumping products of this kind. The properties of the pumped liquids form the design features of bitumen pumps. The main features of such units are the presence of a heating jacket. The seals of such a pump must be resistant not only to hydrocarbons (oil and petrol resistance), but also to high temperatures and harsh operating conditions. These pumps use highly resistant fluoroplastic bushings and seals.