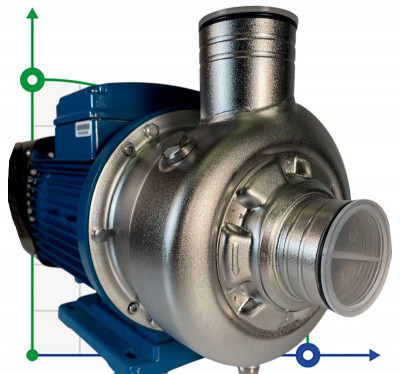

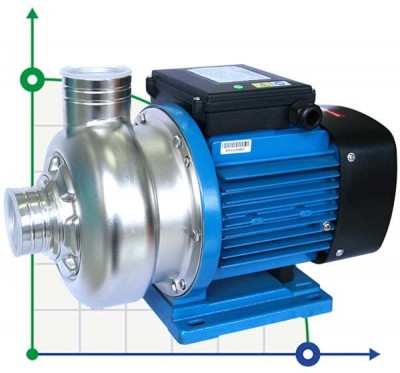

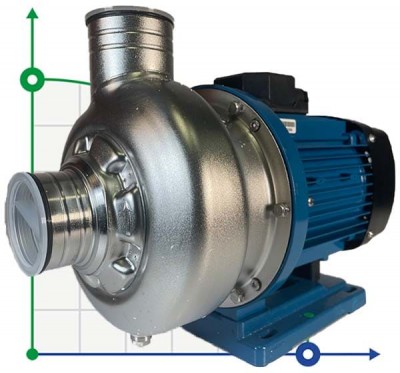

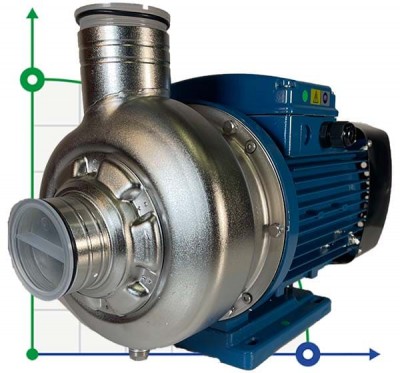

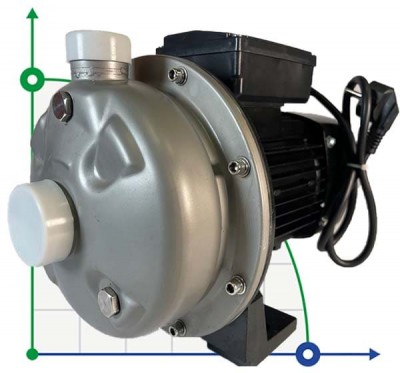

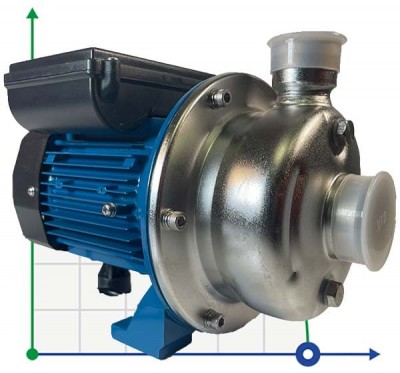

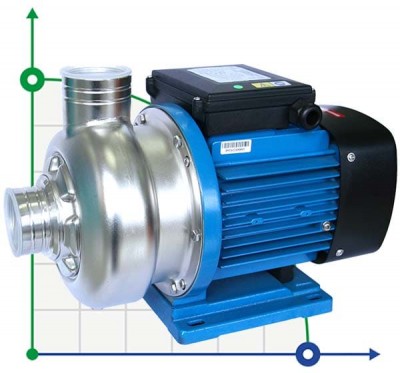

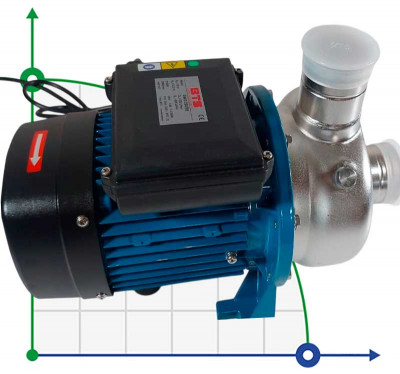

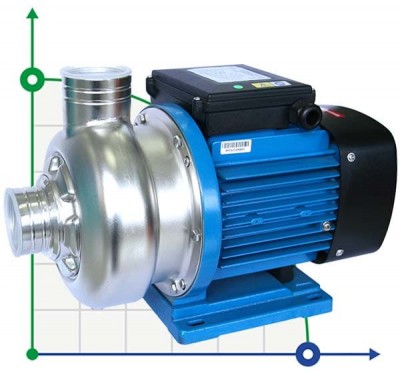

Pumps for milk, whey, dairy products in the production of dairy drinks. Stainless steel milk pumps, hygienic food pumps. Stainless steel of the pump casing, impeller, bottom, complete with a mechanical seal, ensures the tightness of the pump. SIP washing with caustic, acids and other reagents used in the production technology.

Parts of industrial pumping equipment designed for pumping raw materials or finished products are made from materials approved for use in the food industry. For the manufacture of body parts, moving parts and seals, the following are used: stainless steel, food grade bronze, non-toxic polymer materials, food grade rubber, etc. Metal parts of milk and whey pumps that come into contact with pumped media are subjected to electropolishing to reduce friction between metal and liquid. The reduction of roughness makes it possible to completely exclude the possibility of the formation of deposits from product residues on the parts of the pumping unit.

The design of the units intended for use in technological lines for the processing of food raw materials provides for the absence of "stagnant zones" in which microorganisms can multiply and the remains of the pumped product accumulate.

To reduce labor costs for maintenance and reduce the cost of operating technological equipment, the milk pump should be easily disassembled, providing convenient access to the "insides" for washing and disinfection, or be adapted for CIP cleaning, that is, for thorough cleaning of the device without disassembling it into parts.