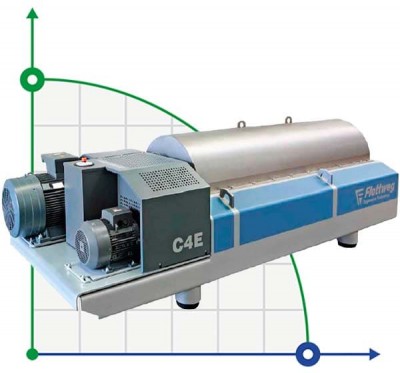

Distillery bard after distillery is cooled in recuperative heat exchangers heating technological environments, then enters the decanter (horizontal centrifuge), where it is divided into a solid fraction - bblend (31...33% absolutely dry substances, hereinafter - DMS) and liquid - liquor (4...4,5% DMS).

Still spirits distillery bard contains about 6 ... 9 % of solids, depending on the quality of grain fed into the process and technological methods used at the plant at various stages of alcohol production. Crude protein, nonnitrogenous extractive substances, fat, fiber, ash, vitamins and trace elements included in the composition of grain raw materials are transferred into the post-alcoholic bard. Use of distillery bard in liquid form is not always rational due to storage problems - proteins entering into its composition after a short time begin to decompose, as well as economically unprofitable to transport it over long distances.

In order to fully use post distillery bard as a highly nutritious feed its multistage processing with obtaining a line of commercial products is proposed. Mass balances and balance of energy resources of distillers' grains distillery are given in tables 2.1.1 and 2.1.2 respectively. Consumption of energy resources are taken by design analogues with recalculation for the mode of operation.