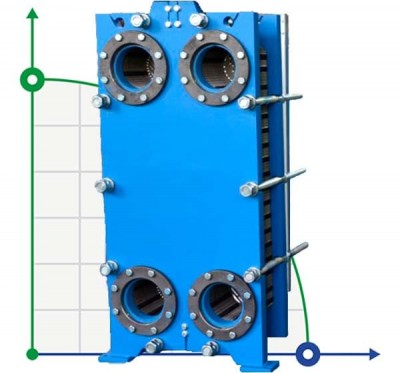

The device and principle of operation of the plate heat exchanger are fairly simple. When the plate pack is pulled together, a number of channels are formed, through which the fluids involved in the heat exchange process flow. Everything the plates in the package are the same, only they are deployed relative to each other 180 °C. This installation of the plates provides an alternation hot and cold ducts. In the process of heat exchange, liquids move, most often, towards each other (in countercurrent), and hot liquid transfers heat through the wall of the plate. In places of their possible overflow there is a double rubber seal, which eliminates mixing liquids. This principle of constructing a plate heat exchanger allows you to quickly modify it, both upward the number of plates, and thereby increase the power of the plate heat exchanger, and it is easy to repair it in case of failure rubber seal or heat exchanger plate. Brazed plate heat exchanger. Sealing plate heat exchanger. Cross flow heat exchangr.