Mixers, agitators, hand mixers for mixing chemical reagents (solutions of acids and alkalis) are designed to be installed directly on a working container in order to prepare and maintain in it a condition suitable for pumping with chemical pumps.

According to the device of the blades agitators are divided into bladed, propeller, turbine, special (anchor, frame, drum, etc.). According to the design, the agitators can be vertical, side, bottom, submersible. The agitator can be driven by an electric motor or an air motor. According to the rotation speed, the mixers are divided into high-speed (propeller, turbine, blade, milling) and low-speed (no more than 1 rev /sec - frame, anchor, screw, spiral, belt, sheet, blade). Depending on what kind of flow the mixers form in the vessel or apparatus, they can be divided into mixers that create tangential, radial, axial and mixed flows. In practice, in most cases, there is a mixed fluid flow, which is the result of the addition of flows of two or even three main types.

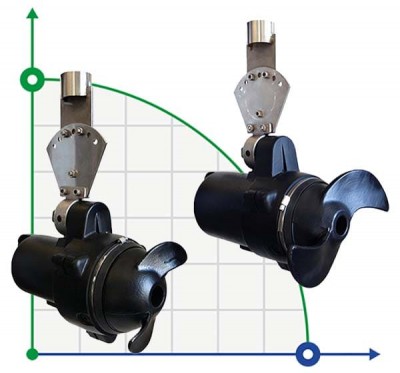

There are various mixers with a choice of material and length of the submerged part, rotation speed, size and configuration of the impeller allows you to choose a mixer for specific customer tasks.