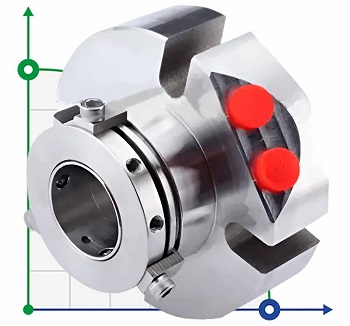

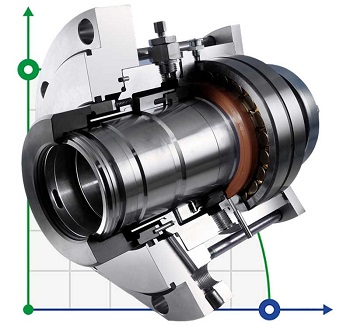

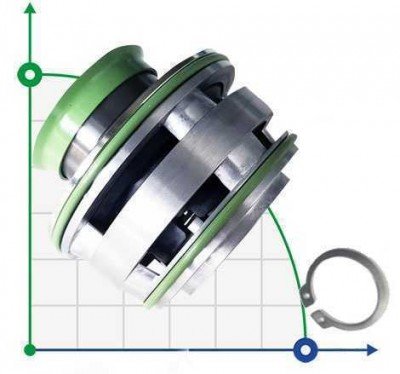

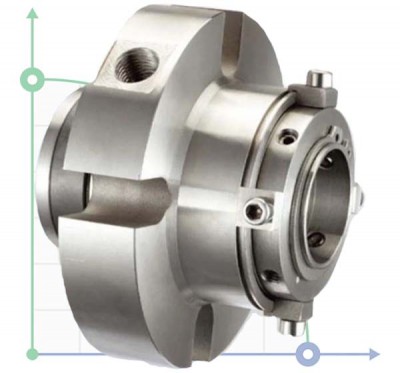

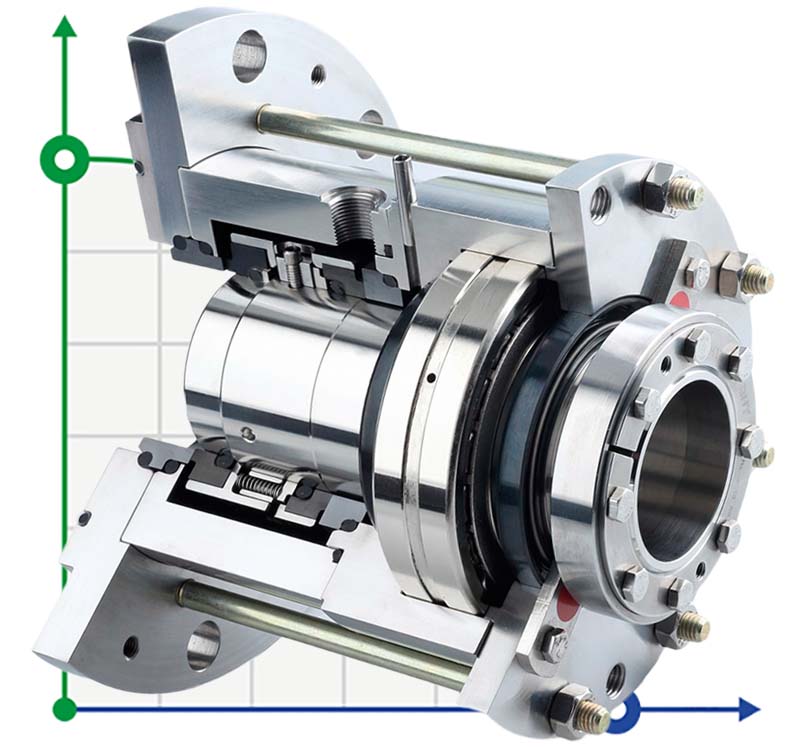

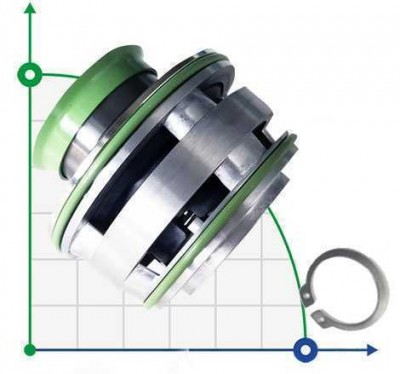

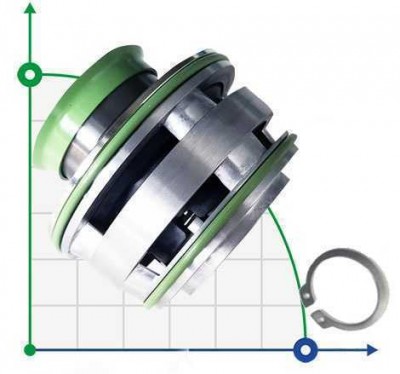

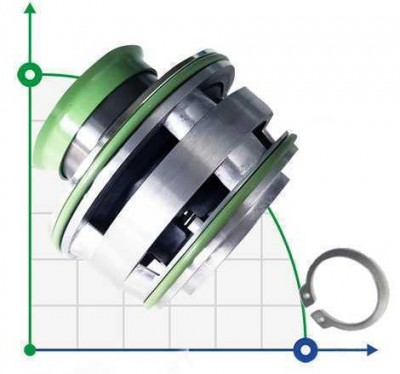

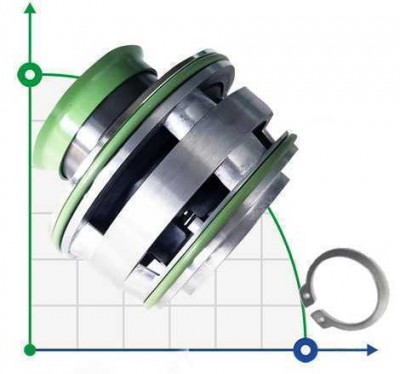

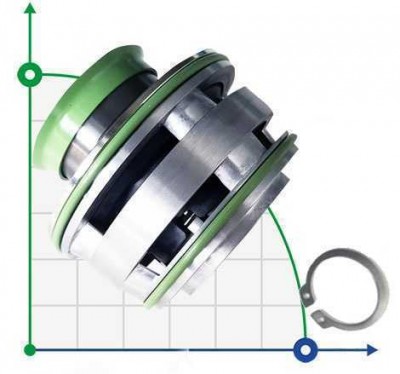

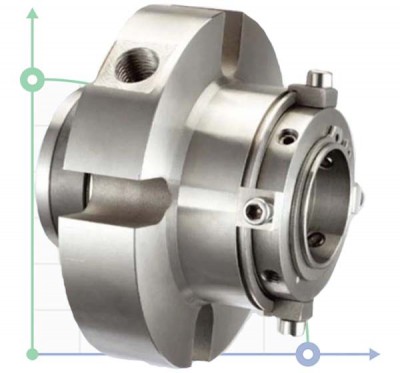

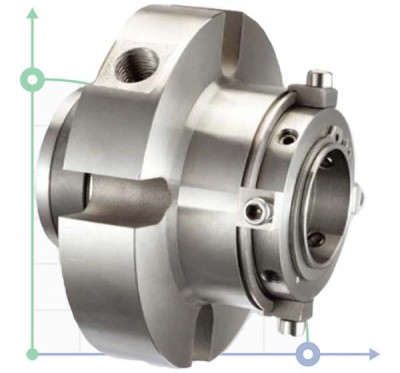

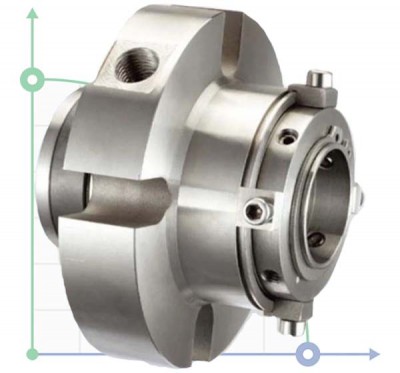

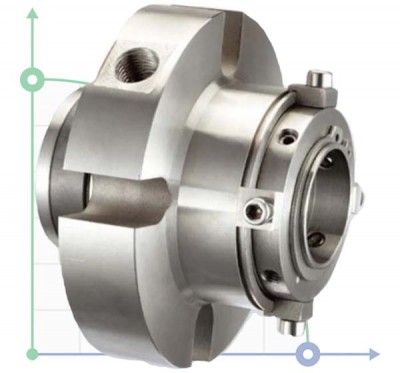

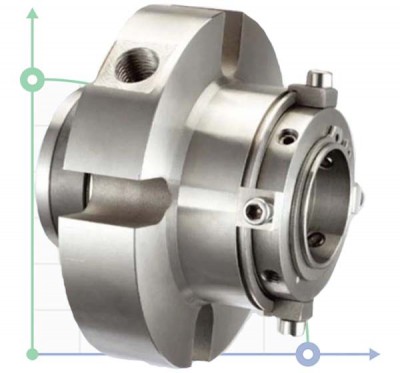

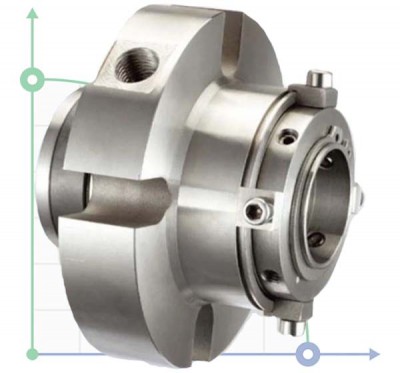

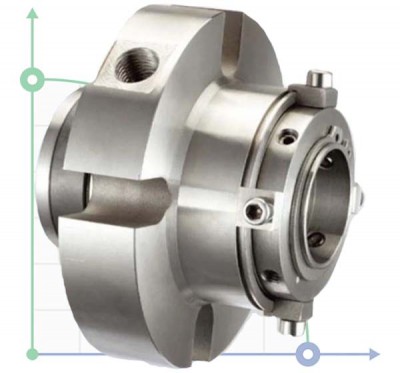

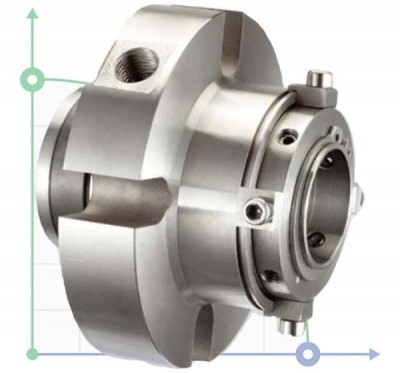

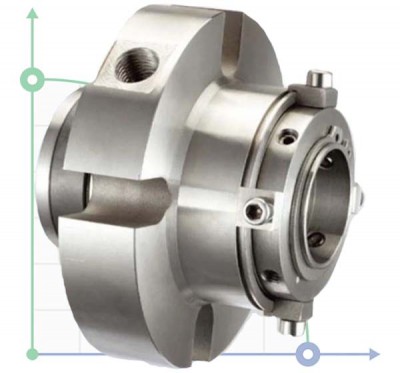

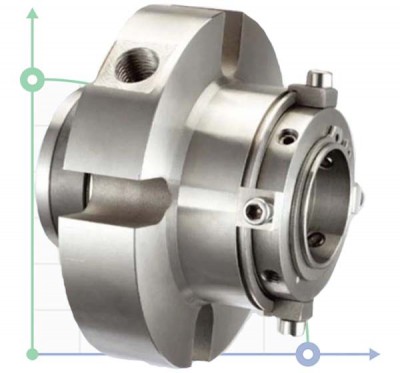

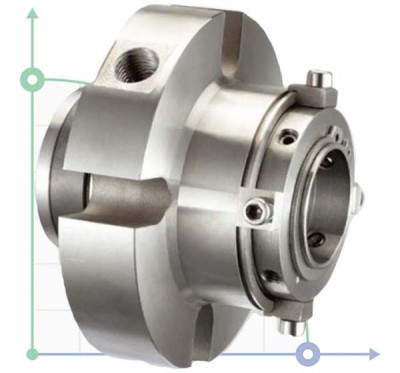

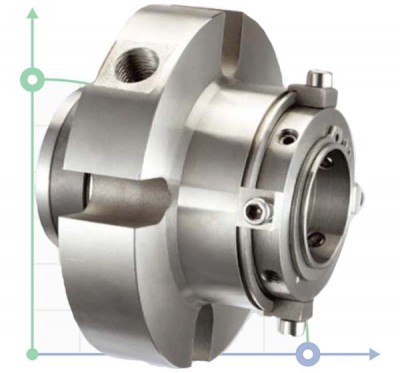

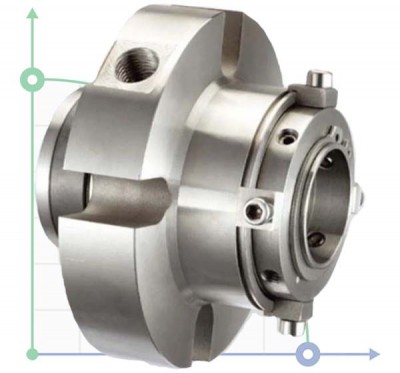

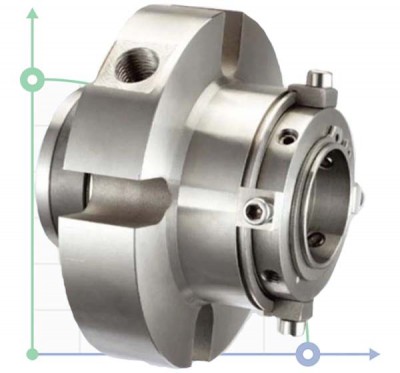

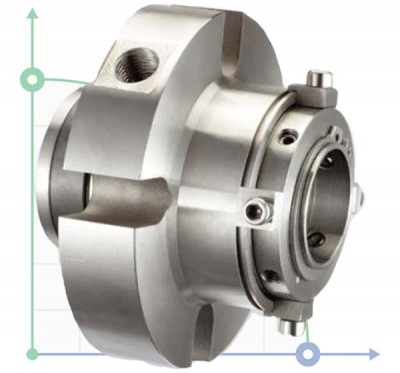

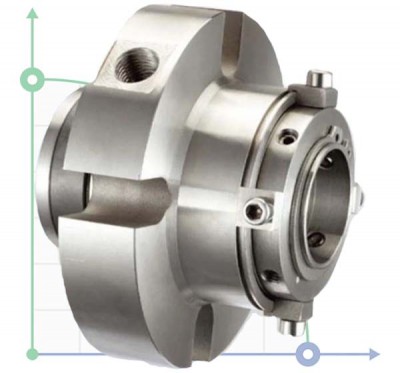

A double (or twin) mechanical seal consists of two independent seals that are installed in a seal chamber outside the pump, which is pumping fluid from an independent source. This design makes this seal ideal for use with hazardous fluids, fluids containing abrasive elements, or corrosive fluids, as only clean lubricant is exposed to the seal faces, thereby significantly extending the life of the mechanical seal.

Double mechanical seals are designed with independent seal faces to better contain process fluid if any of the seal elements are damaged.