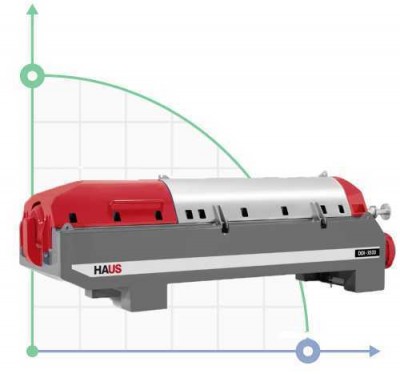

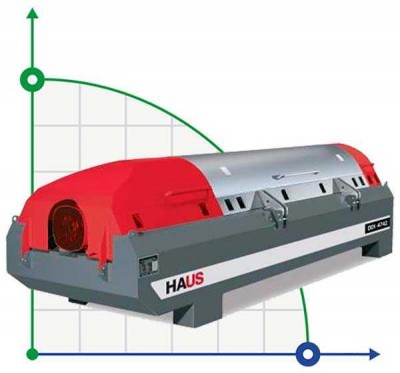

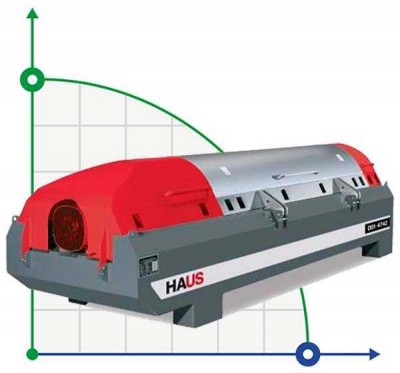

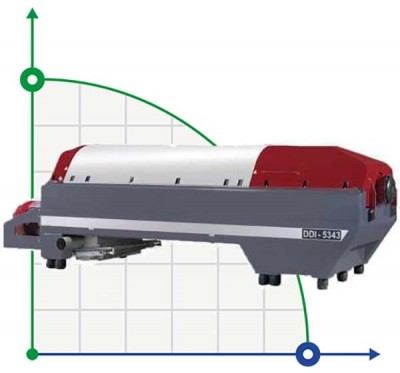

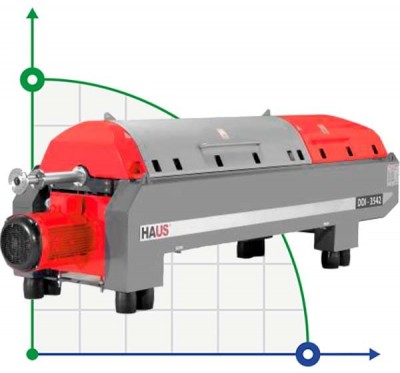

Decanter centrifuge or the decanter is a horizontal centrifuge with a cylindrical-conical rotor for the continuous separation of solids from suspensions using a screw. This type of equipment, due to its simplicity and efficiency, has been widely used for the disposal of oil sludge.

Oil sludge is a physical and chemical mixture, which includes oil products, water and mechanical particles. When oil sludge passes through a decanter centrifuge, the main volume of mechanical impurities is removed from it, as a result of which a minimum amount remains in the mixture, which is removed at the second stage of purification using a filter. To obtain the final product, it is necessary to dehydrate the mixture, after which the oil product is sent to the refinery for further “upgrading” or used as boiler fuel.

The oil sludge enters the inner part of the rotor through a pipe. Due to the action of centrifugal forces resulting from the rotation of the rotor, mechanical particles almost instantly settle on the walls of the rotor. The auger, rotating at a slightly higher speed, continuously moves the impurities into the conical part of the equipment, where the separated solids leave the inside of the rotor and enter the temporary storage bin. The liquid phase moves between the turns of the screw to the end of the cylindrical part of the equipment and is discharged.

The main advantages of the decanter centrifuge are a high degree of purification, small overall dimensions and small losses of oil products. From the foregoing, it follows that the decanter centrifuge, with small overall dimensions, has a high productivity and degree of purification, which can make this equipment an integral part of the technological process for the disposal of oil sludge.