The ultrafiltration unit is a prefabricated structure consisting of an ultrafiltration module, a flushing pump unit, a coagulant dosing unit, a flocculant dosing unit, a system chemical flushing unit, an automation and control unit, piping and shut-off and control valves. Optionally, the installation can be equipped with coagulant and flocculant dosing units, a feed water pump, a wash water tank and instrumentation. It is also possible to vary the degree of automation of ultrafiltration plants.

Microfiltration is a baromembrane process used to separate aqueous colloidal systems (suspensions, emulsions). Microfiltration is closest to conventional filtration, but it is still not. The pore size of microfiltration membranes varies from 10 to 0.5 microns. Microfiltration applications have no clear boundaries. Using microfiltration as a preliminary preparation step.

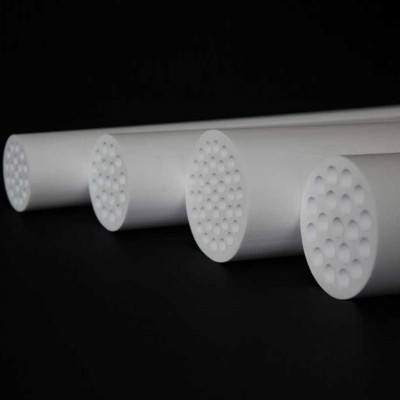

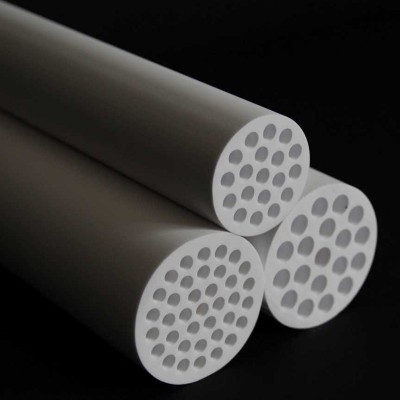

Ultrafiltration is a baromembrane process that occupies an intermediate position between reverse osmosis and microfiltration. The pore sizes of ultrafiltration membranes vary from 0.05 μm to 1 nm. A typical application of ultrafiltration is the separation of macromolecular components from a solution.

Currently, ultrafiltration membranes are widely used in the following areas:

Nanofiltration is a membrane process that removes from water multiply charged ions and molecules 0.01 - 0.001 microns in size, molecules of organic substances weighing more than 150-300 Da (Dalton), as well as viruses. Nanofiltration membranes are capable of retaining ions with a valence of more than 1, providing deep water softening. Singly charged ions (NaCl) are trapped with an efficiency of no more than 50%. Heavy metal ions practically do not pass into the permeate, as well as organic impurities with a molecular weight of more than 150-300 Da (Dalton), which helps to reduce the color and oxidizability of the treated water.