A heat exchanger is a technical device in which heat exchange is carried out between two media having different temperatures.

According to the principle of operation, heat exchangers are subdivided into recuperators and regenerators.

Heat exchangers are used in the technological processes of oil refining, petrochemical, chemical, nuclear, refrigeration, gas, food and other industries, in the energy and utilities

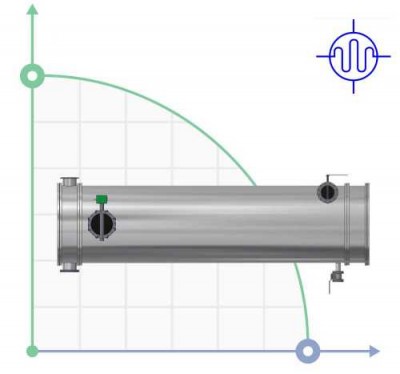

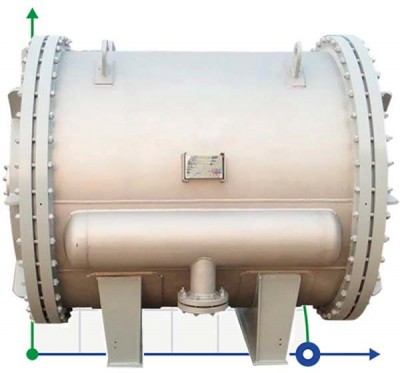

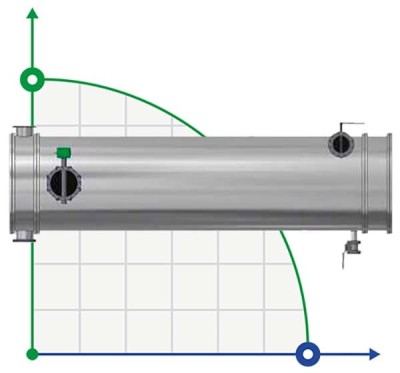

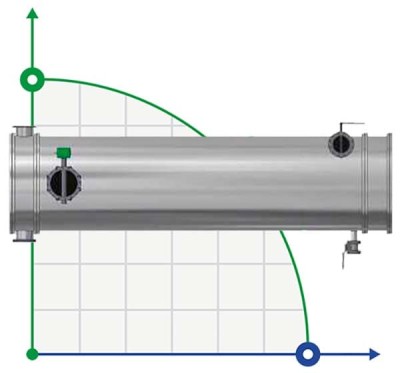

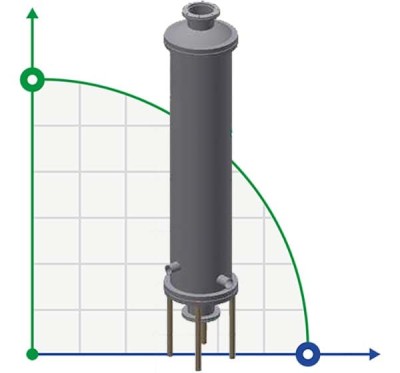

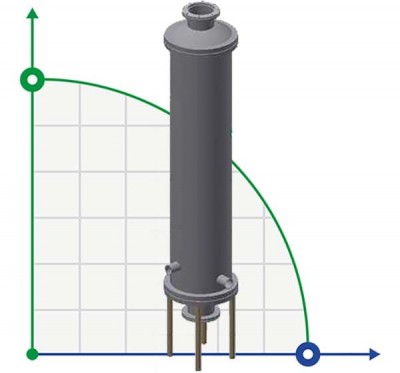

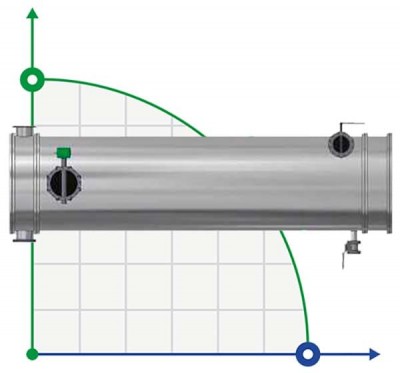

Shell-and-tube, in which the passage channels for the moving media involved in heat exchange are formed by tubular elements. In this case, a pipe or a group of pipes for the passage of one coolant is placed inside another pipe - a casing, through which another coolant passes.

The advantages of shell-and-tube heat exchangers are ease of manufacture and low cost, the possibility of using thick-walled materials, to ensure operation at high operating pressures and temperatures, there are demountable models with the ability to dismantle the tube bundle for maintenance and repair.

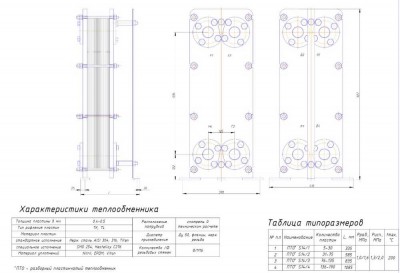

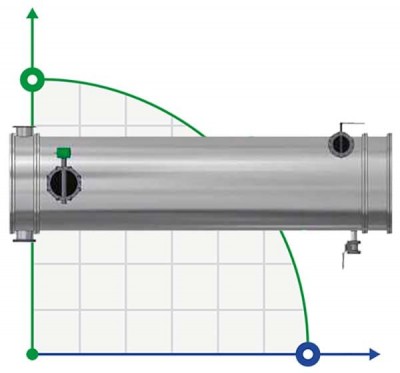

Among the shortcomings, it should be noted the relatively low heat transfer coefficients and, as a consequence, the large heat exchange surface area, due to which the shell-and-tube devices are distinguished by their large dimensions and weight. Lamellar, in which heat exchange between two media is carried out through contact surfaces - plates made of corrosion-resistant steels. Often, such plates, sealed with gaskets, soldering or welding, form closed passageways for heat transfer fluids.

Plate heat exchangers, in comparison with shell-and-tube heat exchangers, are characterized by high turbulence of the media in the channels, high heat transfer coefficients; they are capable of transmitting large heat power with the same heat exchange area as shell-and-tube heat exchangers. The efficiency of plate heat exchangers is considered to be the highest today.