By their chemical essence, vegetable oils are complex multicomponent systems. These systems consist primarily of glycerol esters of fatty acids of various compositions, as well as substances that can be dissolved in them to varying degrees. Initially, vegetable oils may contain impurities that can reduce their quality and (or) presentation: free fatty acids, phospholipids, aromatic substances and pigments. With this chemical composition, we are dealing with the so-called raw oil, which has just been isolated from seeds and fruits and has not yet been subject to any processing.

At its core, vegetable oil refining is the separation of suspensions. It is classified depending on the movement of which phase occurs relative to the other. During sedimentation, particles move relative to a continuous medium, and during filtration, the dispersion phase passes through a concentrated disperse phase. It has been proven that in the case of centrifugation of heterogeneous products, it is possible to remove not only suspended impurities, but also water.

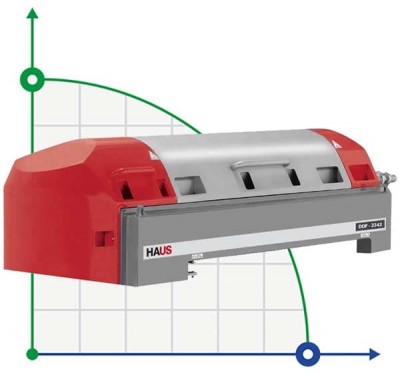

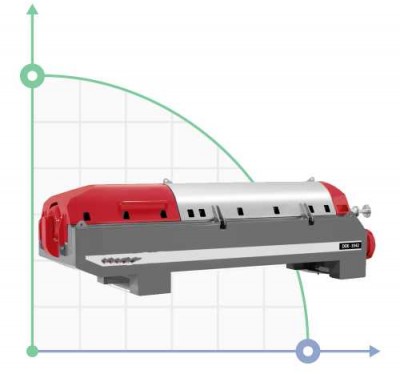

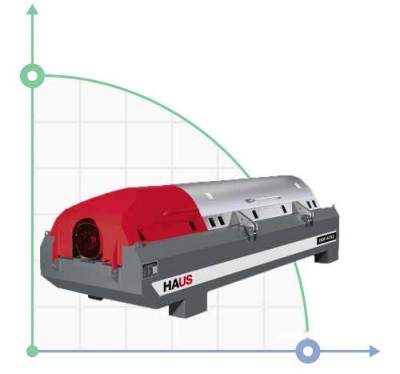

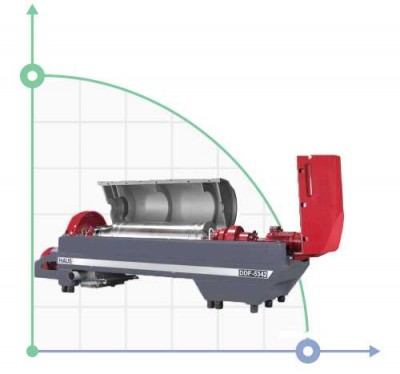

An indicator of the efficiency of a centrifuge can be the separation factor and the productivity index. For example, conical centrifuges have an average performance class of approximately 3 times greater than cylindrical centrifuges. If we are talking about centrifuges, the basic purpose of which is the purification of vegetable oils, then the most important indicators are productivity at a given degree of purification, as well as the dependence of quality indicators on the parameters of the centrifuges, the initial properties of the oil and filter parameters.