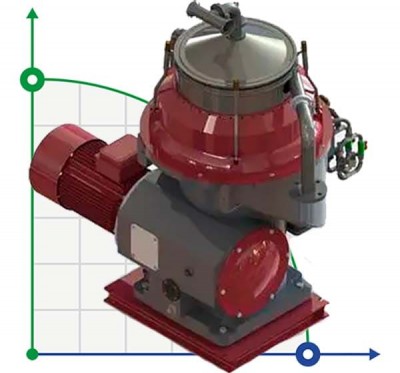

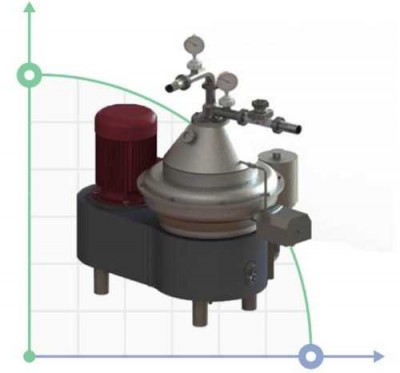

Disc centrifuges, industrial centrifuges for separating liquids, solids, gases with the highest precision and low operating costs. Proven, reliable technology used in the food, oil, pharmaceutical, chemical and waste water industries.

The separation process takes place inside a rotating drum. The feeding is carried out into the rotating drum of the centrifuge from above through a fixed inlet, and the medium to be processed is accelerated in the distributor before entering the stack of plates. The purpose of the distributor is smooth acceleration of the supplied fluid.

The separation of liquid and solid phases occurs in the space between the trays, while the liquid phase (fat) moves through the stack of trays towards the center of the drum, is discharged through the branch pipes and enters the collecting manifold. Water and solids, separated from the fat, move to the periphery, the water is fed through channels in the upper plate into the pressure chamber, where it is pumped out of the rotor by means of an integrated pressure disc.

Solids are collected at the periphery, from where they are periodically discharged through a cyclone separator. The discharge of the solids is provided by a hydraulic system, which at predetermined intervals moves down the movable bottom of the drum, thus opening the discharge channels. Centrifuges provide periodic discharge of the solid phase while simultaneously separating two mixed and mutually insoluble liquid phases of different densities.

Centrifuges are supplied in a range of optimized designs suitable for a wide range of applications, including separation of pre-press broth, glue water and extracts. Other tasks include refining fish oil, liver oil, animal fats, oils and similar products to extract excess yeast, microorganisms and cell debris during the production process on a continuous basis. Gentle action with low shear forces in the centrifuge ensures high viability of the yeast and high quality of the recovered beer.