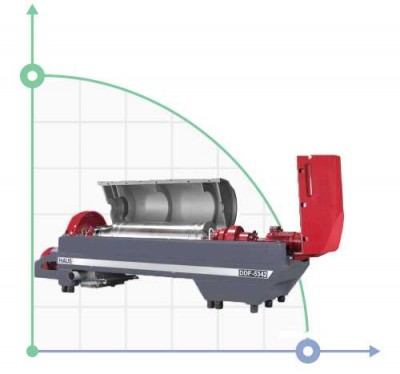

One of the most popular milk processing products - casein and lactose - are distinguished by their nutritional value. The equipment used for the production of casein and lactose opens up new perspectives for more efficient processing.

Casein is a special form of protein that is precipitated from skim milk, retaining up to 80% of the protein contained in ordinary cow's milk. Lactose is a sugar found in cow's milk. Which is composed of glucose and galactose. It is a by-product from casein processing and cheese making. Cow's milk, which is the source of both casein and lactose, is first separated into cream and skim milk. Cream is used in the production of cheese, while skim milk is used in the production of casein.

Whey made from cheese and casein can be used to make lactose. For casein, the skim milk is heated to reach a pH level at which precipitation can begin, acid is added to it. The solids are then separated from the whey. Wet casein is dried and packaged for further processing. For the production of lactose, whey from cheese or casein is first mechanically separated to remove any particulate matter. The clarified whey is defatted, evaporated and crystallized. Lactose crystals are separated and this lactose is then dried and packaged.